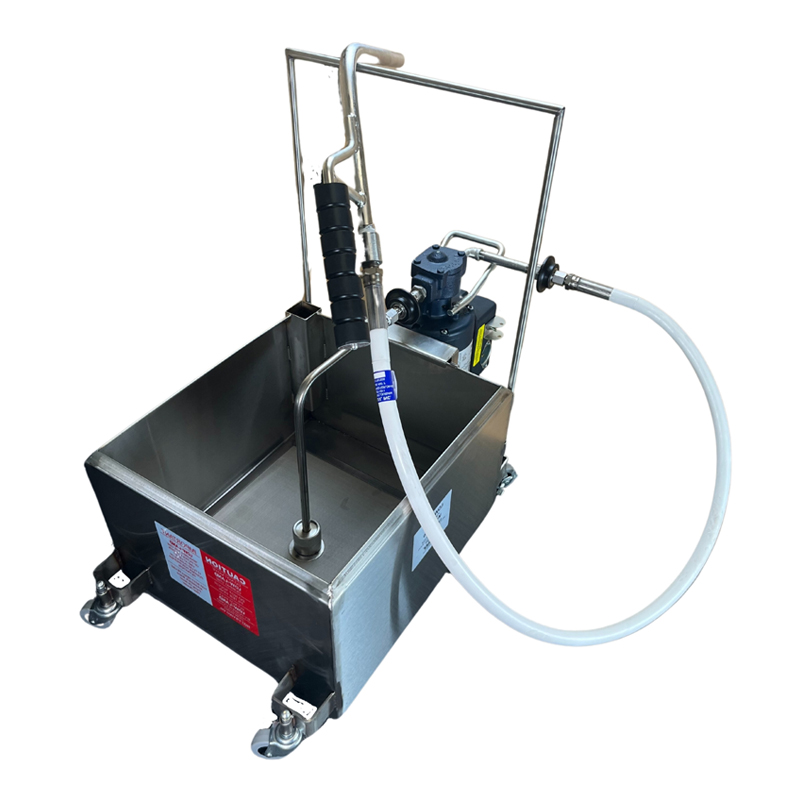

Low-Boy J-60 Filter Machine with Filter Leaf Screen

$3,620.00

Robust oil filtration system – extend your cooking oil’s life effortlessly The robust Low-Boy J60 with a filter leaf screen offers mobility and ease of use in commercial settings. It is equipped with a powerful 5gpm 1/3 hp pump and motor assembly, ensuring speedy removal of large debris and carbon, enabling you to prepare light, crisp, and delicious food. When used with MirOil Frypowder, it easily eliminates the heavy crumb load, sediment, and soluble impurities, effectively doubling your fry oil’s lifespan.

UPC: 00084753001705

Compact and Mobile Design

The J-60 includes a stainless steel filter tank mounted on four ball-bearing swivel casters, enabling easy maneuverability across commercial kitchen spaces. Its compact design not only allows for straightforward storage but also makes it an ideal choice for kitchens handling heavy crumb loads, ensuring that mobility does not compromise the machine’s capacity and functionality.

Enhanced Safety and Convenience

Equipped with a 5’ high-temperature return hose that features a non-heat conducting handle, this machine provides added safety for users. Quick disconnect insulators further enhance its usability by facilitating simple assembly and disassembly, making it highly suitable for fast-paced kitchen environments where time and safety are paramount.

Improved Filtration Features

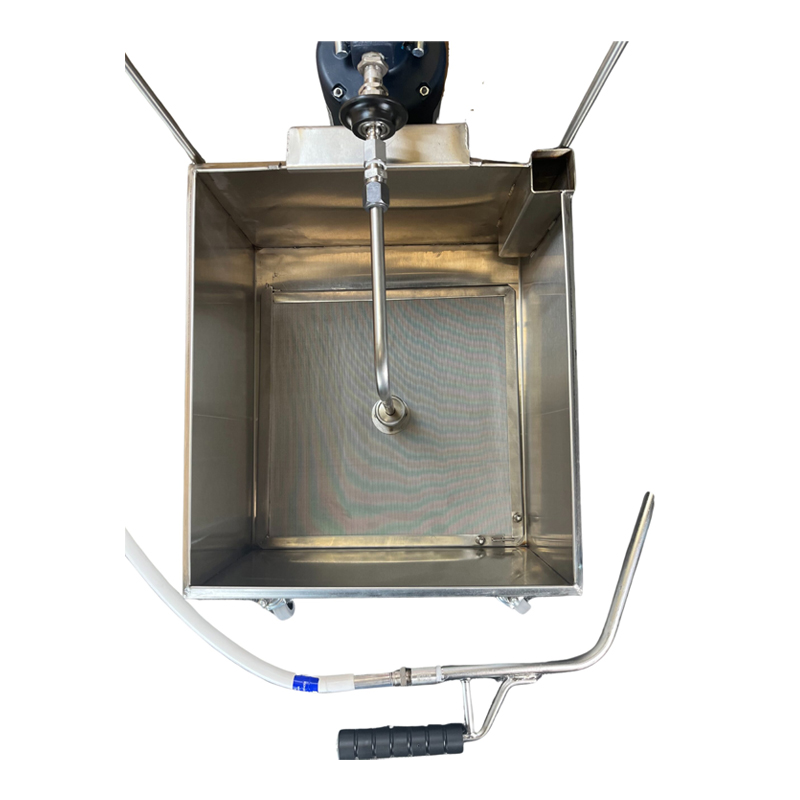

This model is equipped with a stainless steel filter leaf assembly that eliminates the need for costly filter paper, enhancing durability and filtration efficiency for both solid and soluble contaminants. Its robust construction excels in handling heavy crumb loads, ensuring reliable performance and prolonged oil life in demanding kitchen environments. Specifically designed for challenging conditions, the LowBoy filtration system stands out in the industry by utilizing a durable screen mesh for filtering. This mesh is highly effective and resilient, making it the preferred choice for customers dealing with significant amounts of flour and heavy crumbs, offering a superior solution where other filters may fall short.

Core Attributes and Benefits

This resilient, portable, and swift oil filtration system effectively removes both solid and soluble pollutants. Constructed with a sturdy stainless steel filter tank and leaf assembly, it guarantees enduring performance and consistent results, notably decreasing the need for costly paper filters. The system’s design focuses on ease of use, allowing for quick assembly and disassembly, which improves both functionality and maintenance efficiency.

Low Boy Directions For Use and Assembly

Standpipe and Filter Assembly

We demonstrate the procedure using a filter paper envelope, applicable regardless of filter media. On a clean, level surface, insert the metal insert into the filter envelope ensuring the threaded fitting emerges through the envelope’s hole. Securely screw the standpipe onto the fitting. Adjust the standpipe to face the envelope’s opening, fold over the envelope, and secure with the provided clips.

Motor, Hose, and Filter Cart Assembly

Position the filter pump motor assembly between two welded tabs at the filter tank’s end. Center the standpipe and filter envelope assembly within the tank, ensuring quick-connect fittings are securely locked. Place the nozzle assembly in the tank’s holster and ensure secure locking of all quick-connect fittings. Attach the filter tank handle to the rear brackets and connect the power—plug the motor into the provided GFCI and connect to a power source.

Low Boy Disassembly and Cleaning Procedure

Once the Low Boy filter machine has cooled and can be handled safely, begin disassembly by unplugging the GFCI and power cord. Detach the hose and nozzle assembly, letting any remaining oil drain back into the filter tank. Remove the standpipe assembly, filter pump motor, and handle. Unscrew the standpipe from the insert and remove the filter clips. Discard the used filter envelope. Avoid using water or cleaning solutions in the pump as it may cause significant damage. Clean any remaining sediments from the filter cart with hot water, dry all parts with a clean towel, and let them air dry overnight, disassembled.

- Capacity: 60lbs

- Tank Dimensions: 18 1/8″ x 16 1/8″ x 10 3/4″

- Electrical specs (includes overload protector): 115V/60 Hz

- Video: How to use the LowBoy Filter Machine

- Downloadable Lowboy Filter Machine Manual 2023

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.